Helping The others Realize The Advantages Of Non Woven Fabric Making Machine

The non-woven bag making machine has a high creation potential along with a program that in no way lets you agree for a lot less In terms of high quality. By incorporating our machines with your production device, you help you save on labor fees and boost the level of producing efficiency.

Applications —Soil stabilization for railways and street building, retaining partitions, added steep earthwork and also for reinforcement of berms and levees.

Reinforcement — Supplies a tensile factor to the soil matrix, thus furnishing additional skilled structural substance. A geotextile need to have the capacity to transfer its power to your soil it is reinforcing.

Is your line dedicated to encounter masks filter media or may perhaps it's simply modified for various filtration products such as pocket filters, cabin air filters and Other individuals?

Made to course of action the precise sort of non-woven fabric applied in your manufacturing line, our gear is effective at dealing with a number of different non-woven components. The next are just a few of the commonest forms of non-wovens that our changing devices is capable of processing:

Spunlace fabrics have more pleasing Attributes as opposed to needle punched fabrics. The everyday apps of spunlace fabrics are wipes, health care gowns, dust cloths, garment and leather interlining etcetera. More quickly charge of output might be reached with spunlacing procedure than that of needlepunching as there isn't a reciprocating mechanical aspect. Other methods of bonding such as chemical bonding and thermal bonding are normally utilized for artificial fibers.

Our spunbond nonwoven fabric making machine can create superior quality PP spunbond fabrics. The spunbond generation line operates stably, with significant output and substantial performance.

Rising automation inside the textiles sector and therefore accelerating here the manufacture of textiles in the market are the important things thought of driving the non-woven fabric-making machine industry. In addition, expanding demand for personal hygiene and toddler treatment items tend to be the supporting things attributing The expansion in the market. Escalating usage of non-woven fabrics in hospitals and clinics for medicinal and hygienic purpose are viewed as to boost the marketplace advancement in the forecast period of time. Expanding cotton costs across the globe and henceforth, rising strain of raw materials usage is The true secret issue restraining the market advancement. Also, the large cost of non-woven fabric making machines owing to servicing Expense may be the supporting component regarded as to hamper the industry advancement in the course of the forecast period.

melt-blown: fiber is bonded as air attenuated fibers intertangle with on their own throughout simultaneous fiber and World-wide-web development.

The adoption of PP spunbond nonwoven fabric making machines brings forth various strengths more than common producing solutions. These strengths incorporate:

These drylaid Net formers work for all sorts of fibers – which includes normal and synthetic staple fibers. After the fiber World wide web is created, it would be fed to non-woven bonding technologies, which could comprise hydroentangling, needle punching, thermal bonding, and support produce the fabrics.

The company expanded its knowledge in providing and setting up entire turnkey factories due to the fact 2014 and now provides a complete nonwoven line showcasing an oven, cooler, and reducing and stacking device in addition to its CAFT technique and Direct-Utilized-Liquid-Technological innovation (DALT) Highly developed spray process for coating and treating fibers.

The soften-blown procedure makes use of substantial-speed incredibly hot air to draw a thin stream of polymer melt extruded with the die orifice. This tends to type ultra-great fibers and condense to the screen or roller, while depending on self-adhesion and turning out to be a non-woven fabric.

Enhanced tenacity during the wet ailment is a vital gain with these types of cotton filters. To enhance power of mattress blankets and industrial fabrics their scrim elements are created of needlepunched cotton.

Jonathan Taylor Thomas Then & Now!

Jonathan Taylor Thomas Then & Now! Taran Noah Smith Then & Now!

Taran Noah Smith Then & Now! Destiny’s Child Then & Now!

Destiny’s Child Then & Now! Justine Bateman Then & Now!

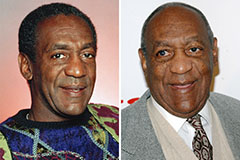

Justine Bateman Then & Now! Bill Cosby Then & Now!

Bill Cosby Then & Now!